FINEST

CRAFTSMANSHIP

Every yacht brings new challenges, and as a leader of men and women, my job is to make sure the job gets done and gets done right. I, like several others of our team, have been at the Conrad Shipyard site since before the founding of Marine Projects in 1989 and some of the younger team members are the 3rd generation of their family to be with the shipyard. During this time our craftsmen and artisans have accrued a broad range of skills and specialties, which is something we develop and pass on to the next generation with every new project. There is a sense of pride with each finished yacht and one of the most satisfying for me has to be Malcolm Miller.

Janusz Kostro, Chief of Production

STEEL & ALUMINUM

Polish welders are world-renowned for providing highest quality at the best value. Marine Projects Ltd. has a proven track record and is an established name in Germany, Netherlands, Norway, and beyond, building steel and aluminum structures up to 1000 tons meeting the highest international regulatory standards.

FAIRING

Shaping a hull and perfecting its surfaces is an art that takes a special dedication and skill. Our team is committed to excellence and does not shy away from challenging shapes and details that require the additional personal touch.

HULL

Our production hall and in-house optimized painting process allow us to create sterile conditions and perform paint jobs of the highest standard. We have implemented rigorous quality control processes but the hull is not ready until our Chief of Production has personally inspected every inch and gives his final stamp of approval.

FURNISHING

Polish craftsmen have not forgotten to work with their hands. Our woodworkers and artisans are trained in a broad range of old-world craftsmanship techniques, which is something we apply to the finish and quality of modern yacht building. Having all the tools and skills in-house allow for superior flexibility and control of quality.

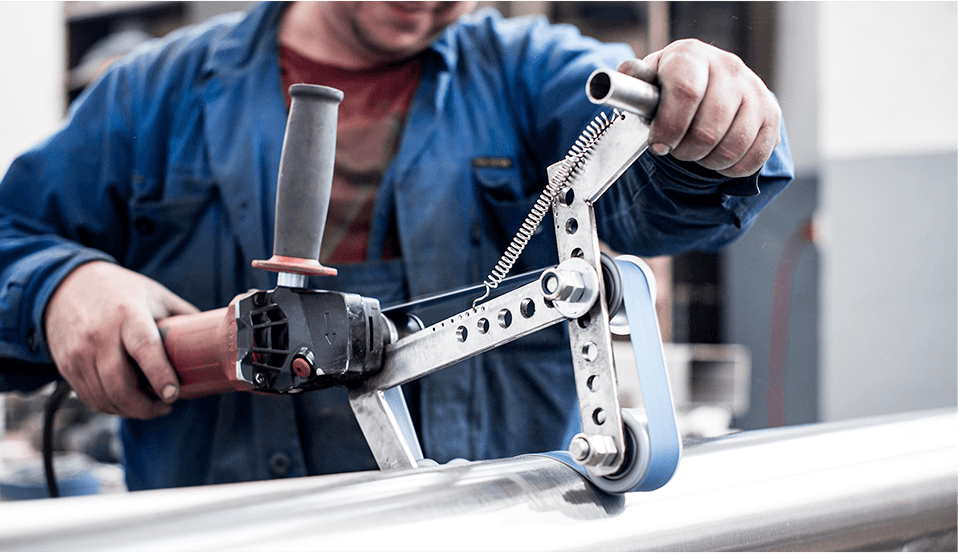

MACHINED & ARTISAN

One of our specialties is working with stainless steel. Whether you prefer machined metal or extravagant stainless steel details, our metalworkers have the latest tools available and don’t shy away from forging metals by hand if necessary.

PRIDE IN THE

There is a personal pride that goes into every yacht that we build. Every yacht is an opportunity to prove that we can build highest Northern European quality yachts that are competitive with those of our western neighbours. This pride and dedication can be seen and felt in the details.